The True Cost of Lost Inventory for Industrial Distributors

Every industrial distributor has to deal with missing inventory or material losses, but many have employees that don't realize the true value of "lost material", which amounts to much more than the replacement value.

Every industrial distributor has to deal with missing inventory or material losses, but many have employees that don't realize the true value of "lost material", which amounts to much more than the replacement value.

Do your employees understand the true value of missing inventory or lost material?

By "lost material" we're referring to:

- Missing or stolen inventory

- Borrowed inventory by sales and technicians that is not recorded and doesn’t find its way back into stock

- Broken or damaged stock

- Obsolete products (less any liquidation value)

- Remnants of an item that are too small to be sold or used (also known as orphan inventory, or scrap)

- Broken Box Quantities

- Quantities of non-stock products ordered for a specific customer that exceed what the customer actually buys (an inventory management issue)

How to calculate the true replacement value of lost or damaged parts

Most distribution employees and technicians don't know that material losses must be paid for with profit dollars. So if a distributor's net profit is 4% (a respectable number for most distributors according to inventory management expert Jon Schreibfeder), the company has a 4 penny profit for every dollar in sales. This means the replacement value of the lost material must be paid out of this .04 cents on the dollar.

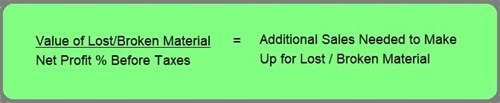

Schreibfeder's equation illustrates the true value of lost or damaged goods:

Divide the value of the lost material by your company's net profit before taxes to get the amount of additional sales you need to generate to make up for the loss. Therefore, if someone breaks a $100 flow switch or hose fitting during the assembly process and your company operates at a 4% net profit margin, the company needs to generate $2,500 in new sales.

$100 ÷ .04 = $2,500

That's 25 times the replacement value!! This value demonstrates how imperative it is that every distributor educate their employees on the true cost of replacing lost inventory, scrap, and unsellable inventory.

How can industrial distributors reduce missing inventory and material losses?

Ensure that you have an ERP software package, like TrulinX by Tribute, Inc., that provides the ability to:

Accurately track inventory so you know where every item is in your warehouse, including stock "borrowed" by your outside sales force

Accurately track inventory so you know where every item is in your warehouse, including stock "borrowed" by your outside sales force- Handle disposition of inventory so you can track and manage damaged, lost and scrap material

- Do cycle counting so missing or mislaid inventory is discovered much earlier

- Barcode your inventory so that the correct item is pulled from the shelf, especially with those long part numbers that may look similar

- Utilize wireless warehouse automation features, like TrulinX Air, to ensure parts are being received, picked, and put away correctly.

- Track rubber lots so that you use the oldest material first or to find the correct length of hose available instead of pulling from a new reel, so unnecessary scrap is reduced

- Have purchasing automated with a system that provides only the needed inventory at the correct time

- Provide warnings or notifications of available substitutions to CSRs on items that incur broken box charges

- Know what items are becoming obsolete in your warehouse

Educating your staff on the true cost of material loss will determine if you need to improve your purchasing processes, charge scrap back to the customer, set up a system for sales team accountability, or do additional warehouse staff training on fabrication of assemblies, etc.

Utilize an industry-specific ERP system to operate more efficiently

A good ERP system designed for industrial distributors, like TrulinX, will help you control costs, help you track every item in inventory, and keep your material losses to a minimum.

Tribute has over 36 years of specialization in the following industries: Fluid Power & Motion Control, Industrial Hose & Accessories, Fluid Handling & Flow Control, Fluid Sealing, Instrumentation & Process Control, Automation & Robotics, and Pump Distribution.

To learn more about Tribute's industry expertise check out our customer testimonials, and to see how TrulinX software can benefit your organization, contact Tribute, Inc.

To learn more about Tribute's industry expertise check out our customer testimonials, and to see how TrulinX software can benefit your organization, contact Tribute, Inc.

Rev. 2-19-20